Brand: Hopex-cable trays 100-600

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 30 sets per Month

Port: TIANJIN

Payment Terms: 30% deposit, the balanced money after the machine finish.

Product Time: 45-60 working days after received the deposit.

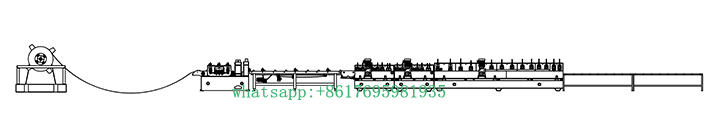

cable tray production line

This cable tray roll forming machine uses hydraulic punching technology, ensuring precise and stable hole processing. The hydraulic punching system delivers high force and efficiency, handling various metal thicknesses with ease. Easy to operate and maintain, it greatly boosts production. The machine’s hydraulic punching design reflects true industrial professionalism.

The machine process flow

Hydraulic decoiler-leveling shearing - servo feeding- punching-cutting - cable tray roll forming part- discharge

|

aw Material Specifications |

Material Type | Galvanized / Cold-Rolled / Stainless Steel |

| Material Thickness | 0.8–2.5 mm (Customizable) | |

| Material Width | Customized according to tray size | |

| Yield Strength | G250–G550 | |

|

Roll Forming System |

Forming Stations | 18–24 stations |

| Roller Material | GCr15, heat treated | |

| Shaft Material | 45# steel, heat treate | |

| Shaft Diameter | Φ70–90 mm | |

| Drive System | Chain drive | |

|

Punching System |

Punching Type | Hydraulic Punching |

| Punching Position | Before forming | |

| Hole Type | Round / Slotted / Customized | |

| Punching Accuracy | ±0.5 mm | |

|

Control System |

Operation Interface | Touch Screen (CN / EN) |

| Inverter | Famous brand | |

| Electrical Components | Siemens or Schnedier | |

| Data Memory | Parameter memory | |

| Motor & Hydraulic System | Main Motor Power | 11 kW *3 sets |

| Hydraulic Power | 7.5 kW | |

| Power Supply | 380V / 50Hz / 3Ph (Custom) | |

| Hydraulic Oil | 46# Anti-wear Hydraulic Oil | |

| Production size | Line Length | 35 meters |

| Machine Width | 2.5 meters | |

| Machine Weight | 25ton |

The cable tray roll forming machine’s parameters can be flexibly customized according to customer requirements, supporting various width, height, and thickness specifications. Its highly customizable design ensures precision while meeting unique project needs. Whether for small-batch orders or large-scale continuous production, it delivers stable and efficient performance.

Our client photo