Brand: Hopex-cable trays 100-600

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 30 sets per Month

Port: TIANJIN

Payment Terms: 30% deposit, the balanced money after the machine finish.

Product Time: 45-60 working days after received the deposit.

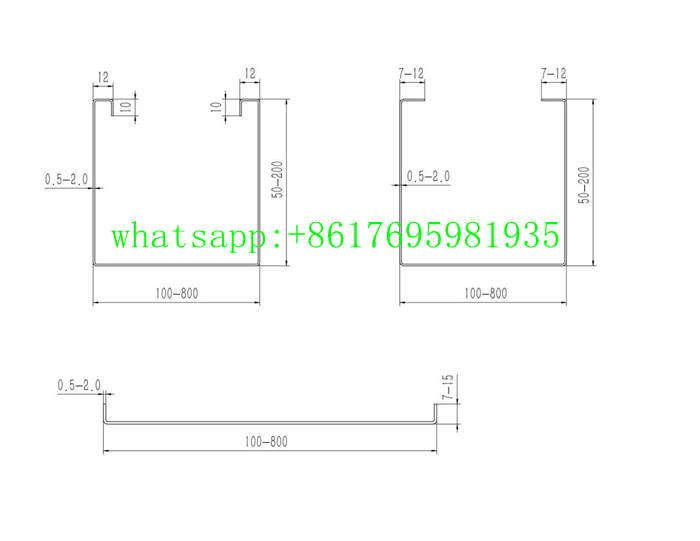

cable tray manufacturing machine introduce

Our advanced cable tray manufacturing machine is engineered for efficiency and simplicity. It features an intuitive automatic profile changeover system, allowing for quick switching between different tray specifications with minimal manual intervention. This capability is managed through a user-friendly digital interface, significantly reducing setup time and complexity.

The highly sophisticated design of this cable tray manufacturing machine translates into operational ease. Operators can execute precise production runs using pre-programmed settings, ensuring consistent quality and maximizing throughput. This professional-grade automation directly addresses core industry needs: reducing downtime, minimizing errors, and enhancing overall production flexibility for various cable management solutions.

The cable tray manufacturing machine assemble part:

This cable tray roll forming machine is designed to save labor and simplify operation. Equipped with an intelligent control system and a clear user interface, it allows operators to get started quickly. With high customization capability, precise forming, and stable performance, it is an ideal solution for efficient and professional cable tray production.

The machine parameter

|

w Material Specifications |

Material Type | Galvanized / Cold-Rolled / Stainless Steel |

| Material Thickness | 0.8–2.5 mm (Customizable) | |

| Material Width | Customized according to tray size | |

| Yield Strength | G250–G550 | |

|

Roll Forming System |

Forming Stations | 18–24 stations |

| Roller Material | GCr15, heat treated | |

| Shaft Material | 45# steel, heat treate | |

| Shaft Diameter | Φ70–90 mm | |

| Drive System | Chain drive | |

|

Punching System |

Punching Type | Hydraulic Punching |

| Punching Position | Before forming | |

| Hole Type | Round / Slotted / Customized | |

| Punching Accuracy | ±0.5 mm | |

|

Control System |

Operation Interface | Touch Screen (CN / EN) |

| Inverter | Famous brand | |

| Electrical Components | Siemens or Schnedier | |

| Data Memory | Parameter memory | |

| Motor & Hydraulic System | Main Motor Power | 11 kW *3 sets |

| Hydraulic Power | 7.5 kW | |

| Power Supply | 380V / 50Hz / 3Ph (Custom) | |

| Hydraulic Oil | 46# Anti-wear Hydraulic Oil | |

| Production size | Line Length | 35 meters |

| Machine Width | 2.5 meters | |

| Machine Weight | 25ton |

FAQ

Q1: What types of cable trays can this machine produce?

This cable tray machine is designed to produce solid bottom trays, ladder type trays, and perforated trays, widely used in industrial plants, commercial buildings, and infrastructure projects.

Q2: What is the production speed of the cable tray machine?

The production speed is 8–10 meters per minute, ensuring high efficiency with stable and precise forming.

Q3: What materials can this machine process?

The machine supports galvanized steel, cold-rolled steel, and stainless steel, meeting various international standards.

Q4: What is the material thickness range?

The standard thickness range is 0.8–2.5 mm, with customization available for special project requirements.

Q5: Can the cable tray machine be customized?

Yes. We provide fully customized solutions, including tray size, punching design, production line layout, and automation level.

Q6: How many operators are required?

Only 1–2 operators are required. The PLC control system is user-friendly and easy to maintain.

Q7: Does the machine include a punching system?

An online hydraulic punching system is optional, with hole shapes and spacing customized according to customer drawings.

Q8: How stable and durable is the cable tray machine?

The machine features a heavy-duty steel frame and proven forming technology, ensuring long-term stable operation.

Q9: What is the delivery time?

The delivery time is around 30–45 days for standard models, depending on customization.

Q10: Do you provide installation and after-sales service?

We provide remote technical support, on-site installation & commissioning, and long-term after-sales service.